Products made from recognised grades of materials (Advice Sheet 5)

Version 8.6, December 2025

1. Introduction

This Advice Sheet covers the requirements for applications for approved products using recognised materials, as well as the requirements to submit an application for a recognised material to be added to the list of recognised materials found in Annex 3 of the List of Approved Products on the dashboard.

The Authorities do not approve individual materials only products that will be supplied directly to drinking water suppliers for use in contact with water intended for human consumption.

However, particular grades of materials for use in the:

- extrusion of pipes;

- factory coating of products; and

- fabrication of products

have been assessed for their effects on drinking water quality. Once approved by the inspectorate, these materials, known as recognised grades, can be used to manufacture products without the need to provide full formulation details or to carry out full testing. Recognised grades have been approved by the Authorities and can be used in contact with drinking water by water companies unless as the recognised grade material has undergone a change (administrative or physical) that has not been notified and approved by the inspectorate. Recognised grades of these materials are listed in Annex 3 of the List on the dashboard. Suppliers holding recognised grade status, will require to apply to the inspectorate for re-approval every 5 years through the Reg31 portal.

An application is required for both products seeking approval that are constructed from a recognised grade of material as listed in Annex 3, as well as a material seeking to be listed in Annex 3 for a product manufactures use. Please note, approved recognised grade holders will be required to apply for re-approval and notify the inspectorate of any changes (administrative or physical).

The rest of this advice sheet refers to specific requirements for applicants using certain types of recognised grade materials.

2. Plastic Pipes

2.1 Pipes made from Recognised Grades of Plastics

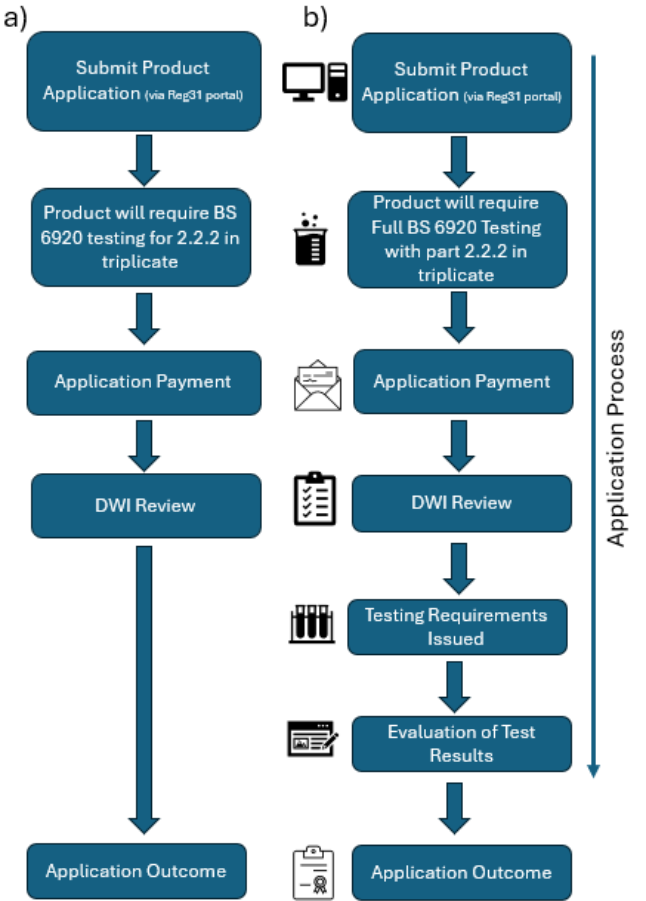

The following requirements apply to pipes made from the previously assessed and recognised grades of plastics and outlined in Figure 1, route a:

- The application must be made by the supplier of pipes to the water industry on the Pipes Systems Application Form. Full disclosure of the formulation of the recognised grade is not required but may be requested.

- The applicant must provide an “Instructions for Use” document for its pipe. Guidance on producing this document is given in Advice Sheet 2.

- The applicant must provide a copy of an odour and flavour test (BS 6920-2.2.2) carried out on test samples, taken at random from three different production batches of the smallest diameter pipe for which approval is sought. Each test must have been undertaken by filling test lengths of pipe incorporating appropriate heat weld or solvent weld joints (as outlined in the IFU).

- That the recognised grade remains valid in Annex 3 of the List, i.e. is within 6-months of the listed expiry date.

2.2 Approval of pipes made from a Grade of Plastic not on the Recognised Grades List

Applications should be made in the normal way as described in Advice Sheet 1 and Advice Sheet 12 where a plastic material is not intended to be added as a recognised grade.

2.3 Applications to add a New Grade of Plastic to the Recognised Grades List

This may be undertaken in two ways as outlined in Figure 1, route b, either:

- A plastic grade manufacturer may make an application, similar to the product application process. Use the Non-metallic construction products application form submitted via the Reg 31 application portal. Any testing requirements would be based on the formulation and how the product is used.

- A pipe manufacturer may obtain approval for a pipe made from a grade of plastic not on the recognised grades list using the normal product approval process. After successful approval, and with the agreement of both the pipe and material manufacturer, the grade may be added to the recognised grades list in Annex 3 of the List on the dashboard. These types of application are often carried out in collaboration.

Figure 1. Compares the two application process routes; For a) the application process for products manufactured from recognised polyethylene materials and b) application process for products manufactured from non-recognised polyethylene materials or the application of material recognition.

3. Factory Applied Coating

3.1 Application for a product using a Coating from the Recognised Grade List

Products incorporating factory applied coatings are subject to the requirements of Regulation 31. Products incorporating coatings which are listed in Annex 3 of the List of Approved Products can be approved after limited testing. Products which have coatings which are not on the List will require full testing for either a product approval or for addition to the list of recognised materials.

Applications for products using recognised coatings should submit the Site and In-Situ Applied Coatings application form through the Reg31 portal, but do not require a full formulation declaration or full testing. The application should:

- note the coating being used and confirm that it is being applied in accordance with the coating manufactures IFU/appplication requirements for that coating;

- provide an Instructions for Use document for the final coated product; and

- The applicant must provide a copy of an odour and flavour test (BS 6920-2.2.2 or BS6920-2.2.1 test report product dependent) carried out on test samples, taken at random from three different production batches of the coated product for which approval is sought.

- Repair requirements for the water company that comply to the coating manufacturers material repairs to be included in the coated product IFU, and that one of the tested products includes a patch repair.

3.2 Application to add a New Coating to the Recognised Grade List

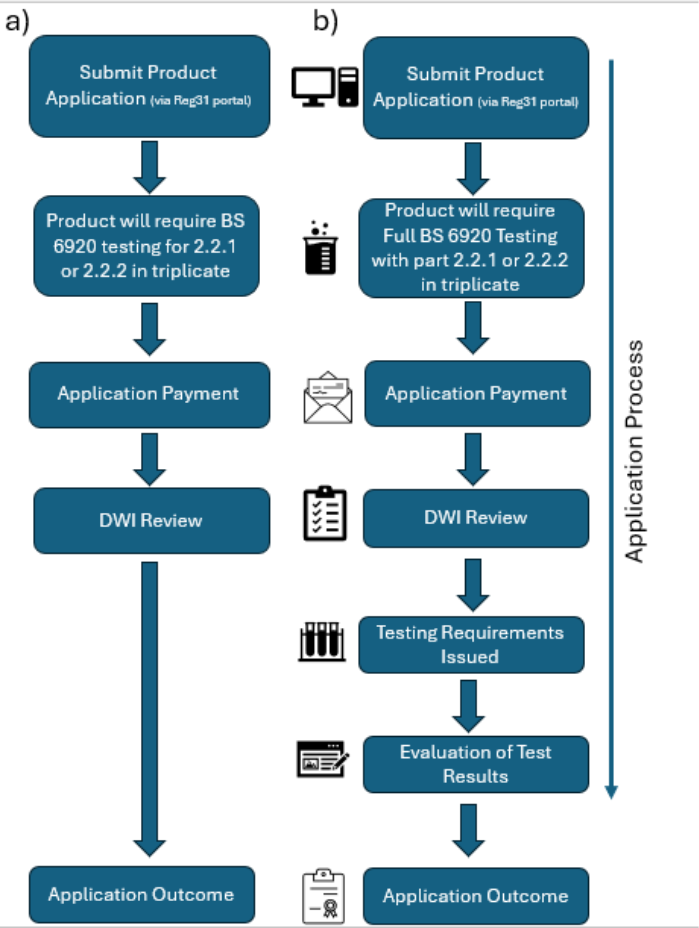

This may be undertaken in two ways as outlined in Figure 2, route b, either:

- A coating manufacturer may make an application, similar to the product application process. Use the Non-metallic construction products application form submitted via the Reg 31 application portal. Any testing requirements would be based on the formulation and how the product is used.

- A coated product manufacturer may obtain approval for a product coated with a coating not on the recognised grades list using the normal product approval process. If the test results are suitable (e.g. there are no other materials present in the product and the surface to volume ratio of the tested piece was suitable) then, with the agreement of both the product and material manufacturer, the coating may be added to the recognised grades list in Annex 3 of the List on the dashboard.

- The coating manufacturer must provide details of the repair requirements for the coating for the factory coating process and for the installation at site (these details may be the same). The repair at installation will be included in the approved product IFU. Additionally, the coating manufacturer will provide details of the maximum free chlorine levels permissible for contact with the final coated product, again for inclusion in the approved product IFU.

- Applications should be submitted using the non-metallic general application form via the portal accessible from the Government Gateway (see advice sheet 12 on our website).

Figure 2, Compares the two application process routes; For a) the application process for products manufactured from recognised materials and b) application process for products manufactured from non-recognised materials or application of material recognition.

4. Stainless Steel

All stainless steel products used in contact with water for public supply must be approved under the relevant regulations, unless considered to be a low-risk product; see Advice Sheet 8.

A number of grades of stainless steel specifications have been tested by The British Stainless Steel Association and had been accepted as recognised grades, these referenced mainly “304 or 316” grades. However, BSEN 10088 provides lists of suitable grades of stainless steel and is maintained as a living document and updated with additional appropriate grades. Within this are grades suitable for drinking water use. Generally, Austenitic grades have been referenced as containing minimum suitability for use with drinking water, with grades “304 and 316” falling within this category. The applications should provide the reference to the grade and suitability for use with drinking water. The other categories of stainless steel that demonstrate suitability can be found in the BSSA operational guidance.

The fabrication method can potentially affect the stainless steel and all stainless steel items must be manufactured in accordance with The British Stainless Steel Association’s Operational Guidance and Code of Practice, available from the BSSA Website.

Fabricators can apply for approval of their products made from stainless steel. The application should be made on the Stainless Steel Construction Products application form, on the Reg31 portal and include an undertaking that all products manufactured for use in contact with drinking water for water company installations will be made from suitable grades and in accordance with The British Stainless Steel Association’s Operational Guidance and Code of Practice.

Products fabricated by manufacturers on the lists are approved provided they comply with the following conditions. Products must be:

- made from stainless steel materials on the list BSEN 10088 stainless steels;

- fabricated in accordance with Operational Guidance and Code of Practice for Stainless Steel Products in Drinking Water Supply, published by the British Stainless Steel Association;

- use other water contact materials (seals, gaskets etc.) in accordance with regulation 311 (either 31(4)(a) or 31(4)(b)). These should be agreed with the water company at the point of specification or included in the application if supplied as part of the product; and

- supplied with documentation to the water company, for their records, to confirm which items supplied are covered by the approval.

4.1 Communication Pipes made from Stainless Steel

Stainless steel communication pipes can be used under regulation 31(4)(b)[1] provided the product meets the requirements in Advice Sheet 8 and would not require regulation 31(4)(a)[1] approval so long as:

- the pipe is made from grades of stainless steel as detailed BSEN 10088 as unlikely to cause a problem in contact with water, and

- drinking water suppliers adhere to “Operational Guidance and Code of Practice for Stainless Steel Products in Drinking Water Supply”, published by the British Stainless Steel Association.

5. Other Metallic Products (Including Metallic Coatings)

5.1 Pipes made from Copper

Copper pipes can be used under regulation 31(4)(b) provided the product meets the requirements in Advice Sheet 8 and would not require regulation 31(4)(a)[1] approval so long as:

- The copper pipes conforming to BS EN 1057 “Copper and copper alloys. Seamless, round copper tubes for water and gas in sanitary and heating applications”; and

- The pipe is installed in accordance with the relevant sections of “Copper Tube in Domestic Water Services: Design and Installation” published by the Copper Development Association.

5.2 Galvanised Steel

Unrestricted use of galvanised steel pipes is not permitted. However, galvanised steel may be suitable for use in certain water compositions. Any supplier seeking to install galvanised steel for use in public water supplies should make an application to DWI for approval following the recommendations in section III of the 4MSI metal composition document – see link below.

5.3 Other Metallic Products and Coatings

Fittings and ancillaries with small surface areas are not exempt from compliance to regulation 31 requirements. The 4MS document for metallic compositions provides a list of suitable compositions that have been tested to demonstrate there is no adverse effect on drinking water, only these compositions should be used by water companies. The suitability for the category of use can be found in the 4MSI metallic compositions document – see link below

Products which do not fall into the category of small surface area as defined in Advice Sheet 8 will normally fall under the full requirements of the relevant regulations. Such products are considered, on a case-by-case basis, by the DWI utilising the positive list updated by the 4MS Initiative “Acceptance of metallic materials used for products in contact with drinking water” and select “Common Approach on Metallic Materials – Part B: Positive list of compositions”.

Footnote

-

regulation 31 of the Water Supply (Water Quality) Regulations 2018 in Wales, regulation 33 of the Water Supply (Water Quality)(Scotland) Regulations 2014, and regulation 30 of the Water Supply (Water Quality Regulations) (Northern Ireland) 2017 ↑