Water safety plan approach to improving the safety of a private supply

This case study concerns a private water supply serving a large estate where the original outbuildings and stables had been converted into 34 domestic dwellings. The source of the supply was two spring collection chambers from which water is piped for 2km into a large brick-built Victorian underground reservoir (20m3).At this point water was treated (UV treatment and pH correction) before being distributed to the properties.

In March 2011, the local authority carried out a risk assessment and this identified a risk of contamination from slurry spreading around the springs. In response, a 50m exclusion zone was created around the springs as a risk mitigation measure. In the following spring (April 2012) several of the householders contacted the local authority reporting discoloured water, with a smell of manure. On investigation slurry spreading outside the 50m exclusion zone was noted and the exclusion zone was extended to include the entire hill slope above the spring to its crest.

In September 2012, the tenant farmer spread slurry on an area outside the exclusion zone (the hill slope on the opposite side to the spring) taking care first to check the forecast was for dry weather. However, within hours, consumers were once again contacting the local authority to report problems with the water supply. The owner of the supply issued boil water advice to all the properties and commenced an investigation.

The owner found that only one spring was affected and immediately instigated his emergency plan. This comprised diverting the spring to waste (through the overflow) and blocking off the pipework to the reservoir to prevent any more contaminated water entering the supply. However, the water in the reservoir was already contaminated. The local authority attended the site and endorsed the owner’s alternative supply arrangement. It was felt that the spring that was unaffected could still be used if the reservoir was bypassed. The reservoir was isolated and flow from the uncontaminated spring (chamber) diverted into a temporary reservoir (two water tanks). The tanks were then connected to existing downstream pipework to the properties. This allowed the reservoir to be drained to waste.

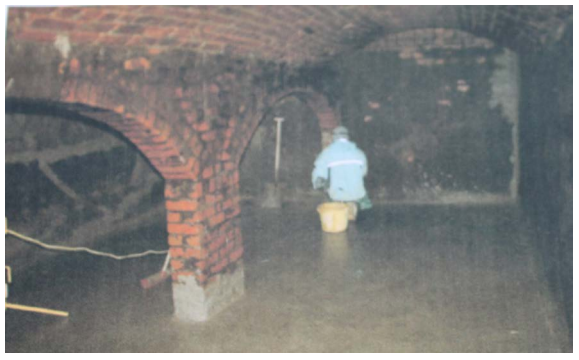

Figure 24: Cleaning inside the vaulted brick reservoir

At the time of the site visit the local authority formalised the boil water advice in a Regulation 18 Notice. The potential risk to health was verified subsequently by the detection of E.coli in samples. The Notice also set out the need for the treatment system to be checked and, if necessary, improved by a competent person, together with cleaning out the reservoir, widening the exclusion zone to above the contour line of both spring sources and development of a water safety plan.

The owner engaged a specialist water contractor to uprate the treatment system so that it was capable of dealing with the raw water quality challenges of high colour and turbidity due to natural organic matter. A sand filter was installed as additional pre-treatment and the owner arranged for annual inspections thereafter. The reservoir was cleaned out by jet spray and then disinfected and flushed, likewise the downstream pipework. While these works were taking place, the owner checked the location and condition of the existing pipework and replaced a section in poor condition. A bypass valve was installed after each spring chamber to facilitate running to waste, enabling timely and effective action in any future event and to improve resilience generally (enabling each source to be operated independently of the other).

Figure 25: Valve chamber

By the date set in the notice (13 December 2012), all the required improvement works were complete, apart from the water safety plan.

During 2013, the supply owner put in place a system of weekly operating checks by a nominated person living on site. These involved weekly visual checks and recording of the UV system and pre-filter to assess whether parts needed replacement. By August the water safety plan was complete and detailed the weekly checks, annual servicing, alternative supply arrangements and instructions on how to use new diversion valves to isolate a source from the reservoir, as and when required.

This case study highlights how the safety of a private supply relies on a comprehensive risk management plan based on the specific risks of the supply. For example, exclusion zones need to be tailored to the situation; the generic 50m rule is only a general guide. Likewise, through the addition of valves, overflows and bypass pipes, the resilience of a supply is enhanced, so it is easy to deal with adverse situations and carry out routine maintenance. The Inspectorate’s risk assessment tool is based on the WHO safety plan approach and its outputs are designed to identify what can be done to develop a comprehensive risk management plan. Specifically the tool is designed to produce action plans that local authorities should be passing on to owners so that water safety planning knowledge is transferred to those who are responsible for the safety of the supply. The Inspectorate recommends that when carrying out the five-year review of a risk assessment, local authorities utilise the action plan component of the risk assessment tool.